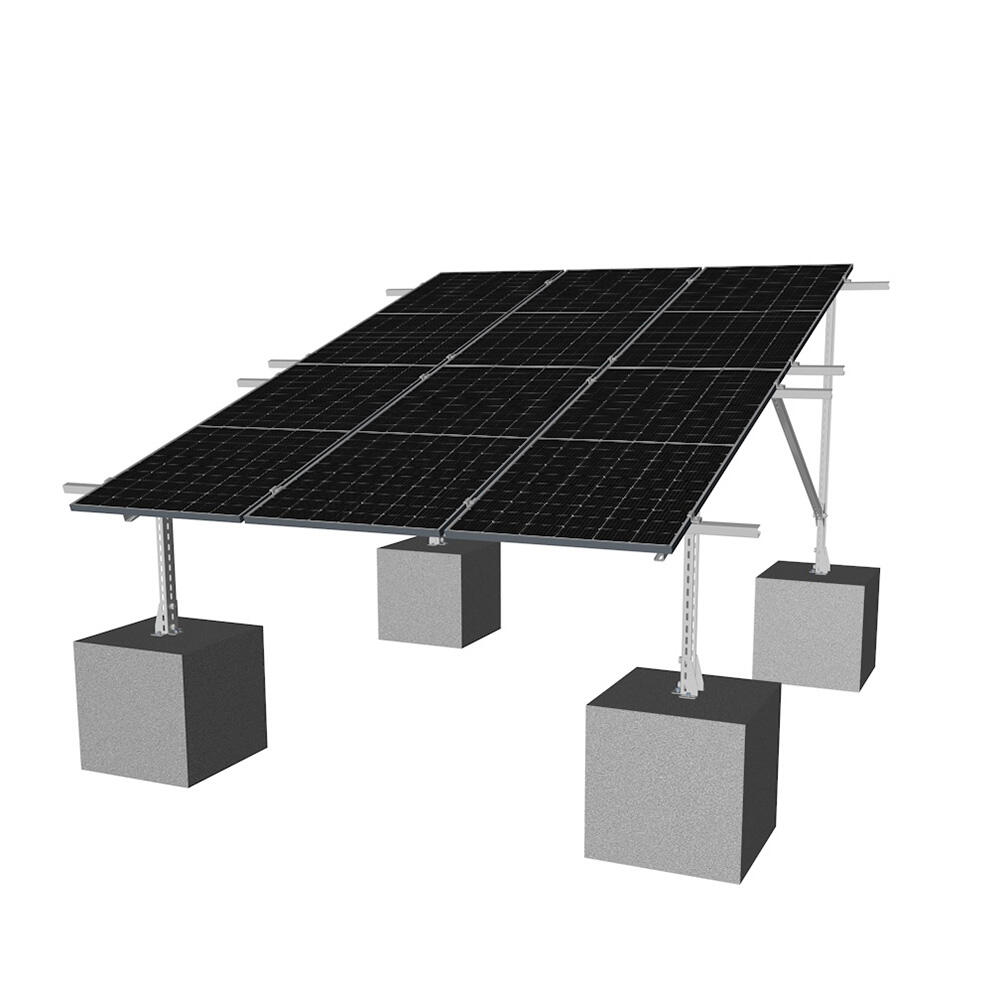

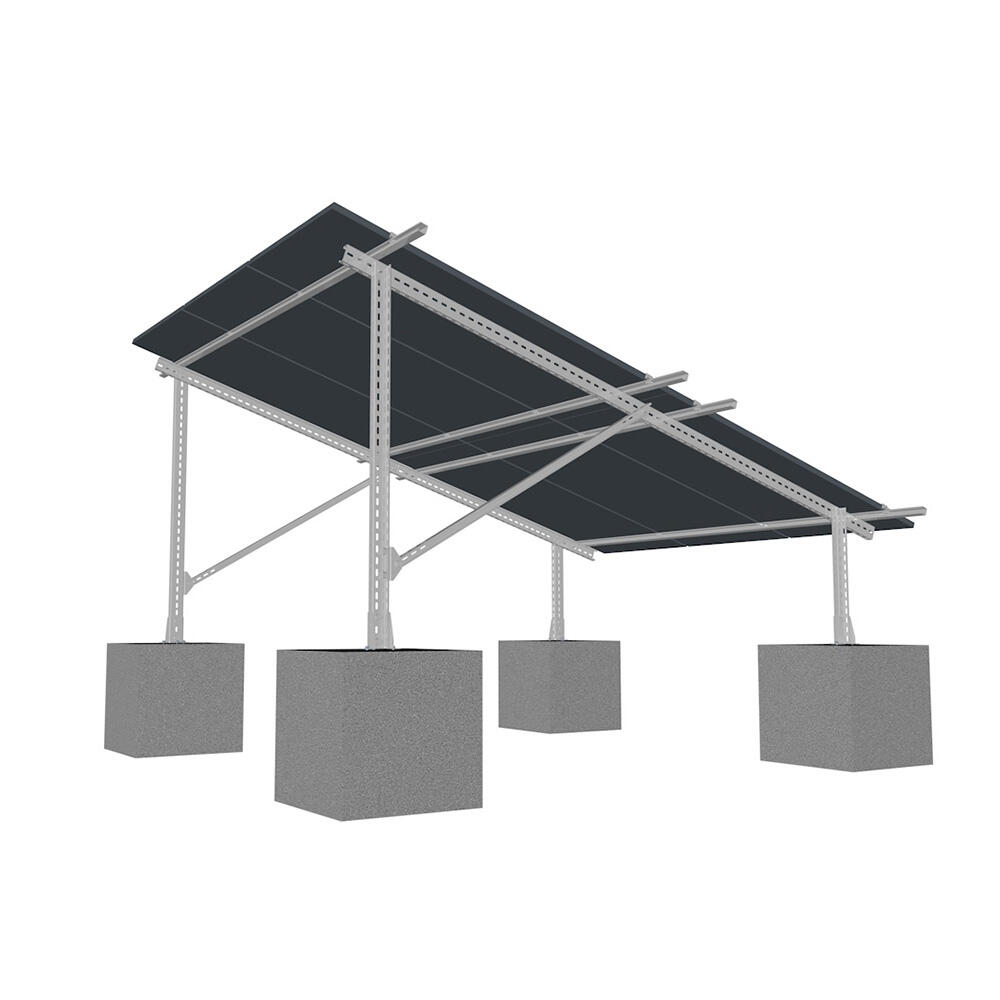

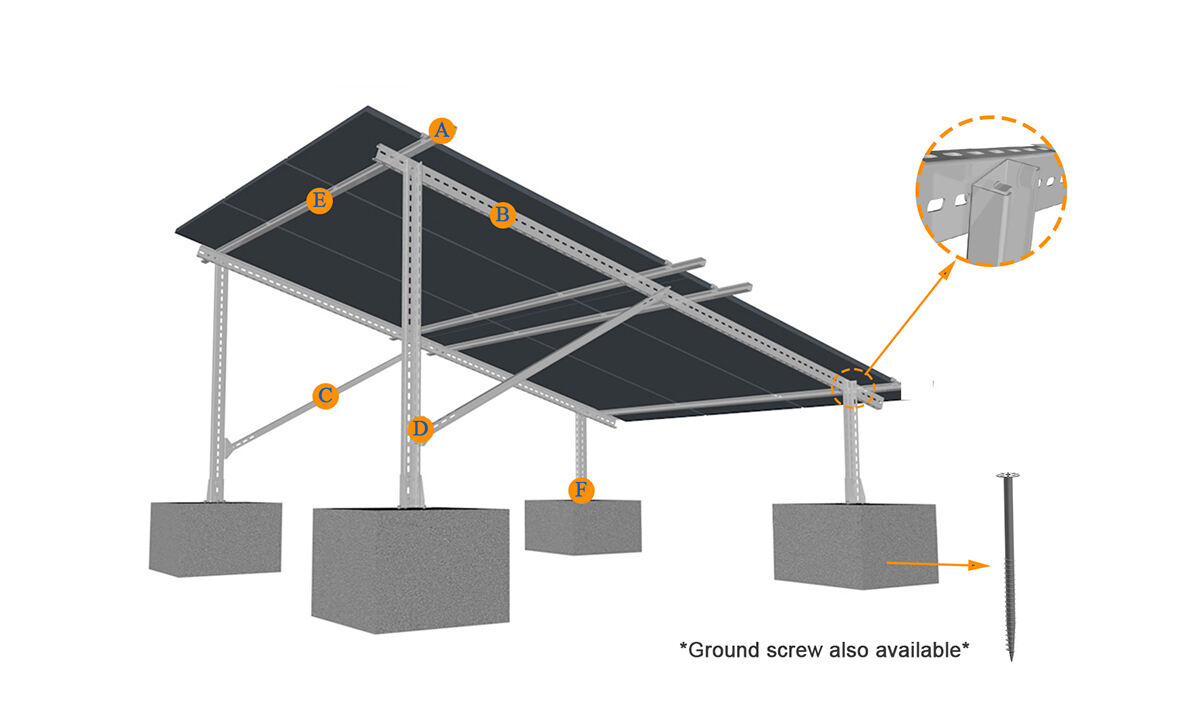

| Application |

Flat roof or open field |

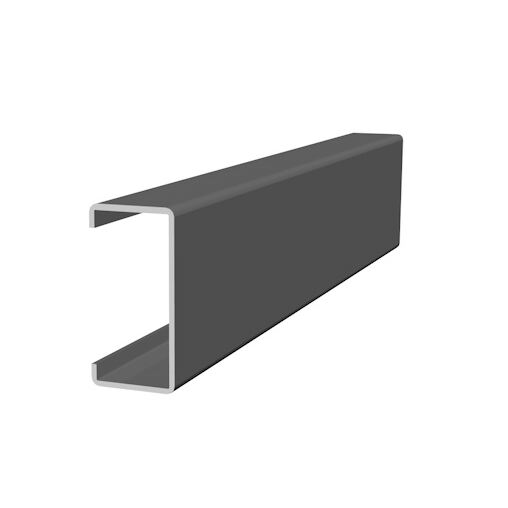

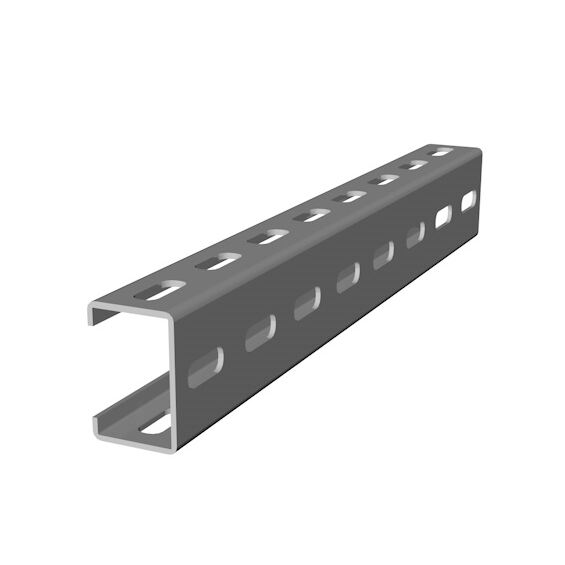

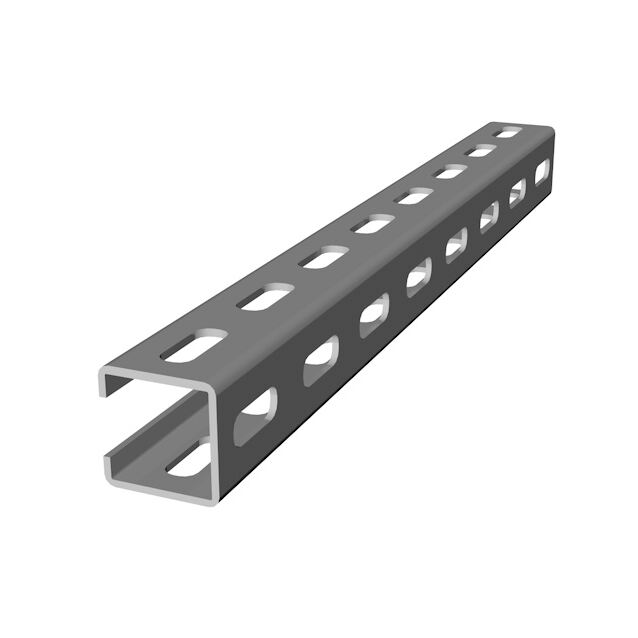

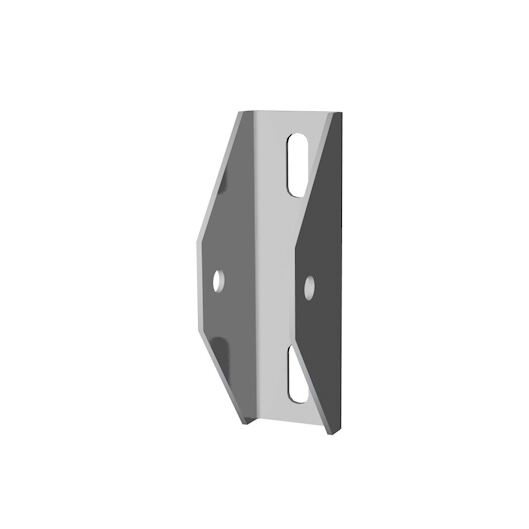

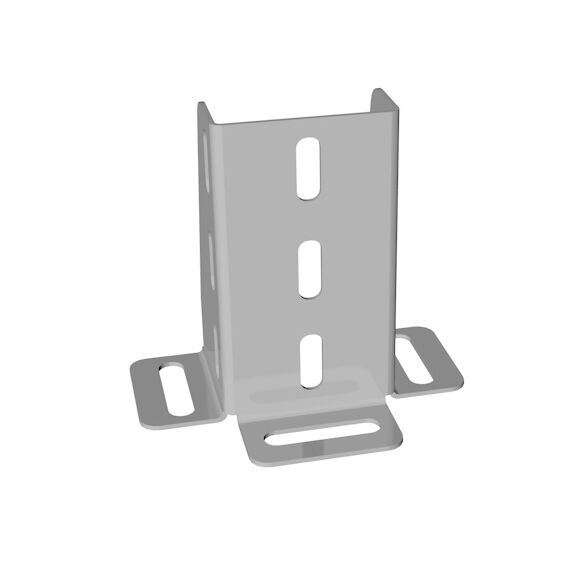

| Material |

ZAM coated steel. |

| Panel Type |

Framed & Frameless |

| Wind Load |

Up to 60m/s |

| Snow Load |

Up to1.0 KN/m² |

| Panel Orientation |

Landscape or Portrait |

| Tilt Angle |

0-45 deg |

| Certificate |

ISO/CE |

| Warranty |

12 Years |

| Service life |

25 Years |

ZAM coated steel is a Zn-Al-Mg ternary alloy coatingsteel. This chemical composition has been chosen toprovide the optimum levels of corrosion resistance, which is about 3 to 5 times comparing with HDG steel. This kind of steel permits all the conventional processing operations possible with standard HDG steel. Inaddition to these many benefits, ZAM coated steel hasa lower friction coefficient which remains stablethroughout forming operations to get a better solarmounting structure.

> Durable Coating: The ZAM coating provides excellent corrosion resistance, ensuring the longevity of the solar mounting structure even in harsh environments.

> Sturdy Ground Mount: Designed for stability, the ground mount system securely holds the solar panels, optimizing their angle for maximum sunlight exposure.

> Easy Installation: The system is engineered for quick and straightforward installation, reducing labor time and costs.

> Versatile Application: Suitable for various terrains, the ZAM-coated ground mount PV system is ideal for large-scale solar projects where durability and efficiency are key.