Aluminum vs. Steel Ground Mount Systems: Core Material Differences

Composition and Structural Properties

In considering ground mount systems, understanding the material properties of aluminum and steel is crucial. Aluminum, noted for its light weight, offers excellent resistance to rust and corrosion, making it ideal for environments that experience high humidity or salt exposure. This resistance significantly reduces maintenance needs and extends the system's lifespan. On the other hand, steel is known for its strength and durability, although it often requires additional treatments like galvanization to prevent rust. Investigating the alloy compositions reveals that steel’s high tensile strength benefits large-scale projects, while aluminum’s higher thermal conductivity can enhance energy efficiency in solar applications by dissipating heat more effectively. Such unique material characteristics play a pivotal role in selecting the appropriate system for specific environmental conditions.

Weight-to-Strength Ratios Compared

When comparing the weight-to-strength ratios of aluminum and steel for ground mount systems, each material presents distinct advantages. Aluminum’s lower weight supports easier transportation and installation, streamlining logistics without compromising structural integrity. In contrast, steel's robustness makes it particularly effective in load-bearing applications, ideal for large-scale solar systems where substantial weight support is required. Even though steel is heavier, its superior load capacity ensures stability, which is crucial for extensive installations. Industry standards highlight that both materials deliver suitable weight-to-strength ratios, allowing design flexibility based on project size and site requirements.

Flexibility in Design and Customization

The design flexibility afforded by aluminum and steel ground mount systems significantly impacts customization possibilities. Aluminum, known for its malleability, enables custom designs tailored to specific installation needs, catering to both standard and unique landscape challenges. This flexibility allows for creative solutions in varying terrains. Conversely, steel’s rigidity offers unparalleled stability, albeit with limitations in design adaptability, particularly in unconventional landscapes. There are many case studies where project engineers and architects have chosen materials based on the needed design flexibility, emphasizing how material choice can drive innovative solutions in diverse geo-architectural contexts.

Durability Showdown: Corrosion Resistance and Environmental Performance

Galvanized Steel vs. Anodized Aluminum Treatments

When it comes to corrosion resistance, both galvanized steel and anodized aluminum offer unique advantages. Galvanization adds a protective zinc layer to steel, effectively safeguarding it from rust and making it suitable for various environmental conditions, such as humid or rainy areas. On the other hand, anodized aluminum undergoes an electrolytic process that enhances its natural corrosion resistance, making it particularly ideal for solar installations exposed to the elements. A study highlighted in materials science journals reveals that anodized aluminum fares better in saline environments compared to galvanized steel, which helps in understanding the variations in corrosion rates under different conditions. This makes aluminum a preferred choice in coastal regions.

Longevity in Coastal vs. Industrial Environments

The performance of aluminum and steel in varying environments highlights significant distinctions. In coastal areas, aluminum often outperforms steel due to its superior resistance to saltwater corrosion, a common challenge in such locales. Steel requires regular maintenance to combat rust in these conditions, potentially reducing its lifespan. Conversely, in industrial environments, where exposure to chemicals or pollutants is more prevalent, properly treated steel can offer extended durability. Reports have shown that with the right maintenance protocols, both materials can achieve a long lifespan, but aluminum often requires fewer interventions in corrosive settings.

Maintenance Requirements Over 20+ Years

Examining the maintenance needs of ground mount systems over a two-decade period provides valuable insight into long-term costs and labor. Anodized aluminum systems generally demand less maintenance due to their inherent resistance to corrosion. In contrast, galvanized steel, while durable, can incur higher costs due to the necessary treatments to maintain its integrity in harsh conditions. Industry experts suggest regular inspections and maintenance checks to ensure system longevity, with documented case studies underscoring the importance of scheduled upkeep. By understanding these requirements, we can better manage resources and optimize the lifespan of both aluminum and steel solar mounting systems.

Structural Capabilities for Solar Installations

Wind Load Resistance (Up to 185 mph Capabilities)

Wind load resistance is a critical factor in determining the structural capabilities of solar installations. To assess the performance of aluminum and steel systems under high wind conditions, engineering tests measure their ability to withstand wind speeds of up to 185 mph. Such tests ensure adherence to industry standards, which dictate design specifications for wind load resistance, especially in windy regions. A well-engineered system offers added safety and durability, making it essential for solar installations located in areas prone to high winds. This alignment with local regulations guarantees that panels can endure demanding weather conditions without compromising efficiency and stability.

Snow Load Capacity and Seasonal Stress

When analyzing the structural capabilities of solar installations, snow load capacity and seasonal stress are pivotal concerns. The performance of aluminum and steel systems in handling snow loads, especially in winter-prone regions, is evaluated through detailed structural analysis. Comparative calculations highlight the significance of material choice, emphasizing how different designs perform under heavy snow conditions typical of certain climates. Selecting materials resistant to seasonal stress is vital to ensure consistent and reliable performance, preventing structural failures during harsh winters.

Span Limitations for Large-Scale Arrays

Span limitations are another critical consideration for large-scale solar arrays. The inherent properties of aluminum and steel influence their span capabilities, which are dictated by specific design methodologies. When material choice is incorrect, failures can occur, as evidenced by various case studies focused on span limitations. Understanding these constraints allows for optimal material selection, preventing issues that compromise the efficiency and safety of solar installations. By addressing span limitations, system designs can adequately support extensive arrays without sacrificing performance.

Installation Realities: Labor, Foundations, and Site Considerations

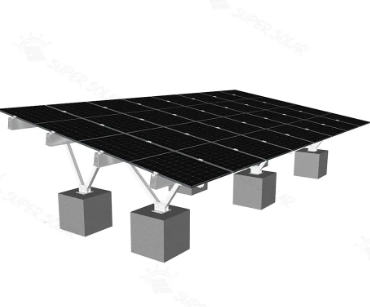

Earth Anchor Systems vs. Concrete Foundations

When it comes to installing solar panel mounting structures, two main foundation options dominate: earth anchor systems and concrete foundations. Earth anchors are particularly advantageous because they require less labor and are more cost-effective compared to traditional concrete foundations. Industry data supports this by showing that earth anchor systems expedite the installation process, often resulting in lower overall project costs and shorter installation timeframes. By evaluating these factors, project managers can make informed decisions that streamline construction while maintaining structural integrity.

Soil Compatibility: Rocky vs. Sandy Terrains

The type of soil at a solar installation site plays a crucial role in determining the appropriate foundation. Rocky terrains often necessitate robust foundation solutions, such as earth anchors, to ensure stability and longevity. Conversely, sandy soils might require different strategies to mitigate shifting or settling issues. Experts emphasize the importance of conducting thorough ground condition assessments before choosing materials and construction methods. Engaging with specialists in geotechnical analysis can provide invaluable insights that guide material selection and enhance construction practices for optimal results.

Equipment Needs for Steel vs. Aluminum Assembly

Deciding between steel and aluminum for solar mounting structures involves not only material consideration but also an understanding of the equipment and machinery required for installation. Steel structures often require heavier tools and machinery, which can influence both productivity and time constraints during assembly. In contrast, aluminum is easier to handle owing to its lightweight nature, simplifying the installation process. Research suggests that recognizing these differences can significantly impact planning, budgeting, and even the project timeline. Being aware of the distinct equipment needs and handling of both materials allows for more efficient project management and preparation.

Cost-Benefit Analysis: Initial Investment vs. Lifetime Value

Material and Installation Cost Comparison

When investing in ground mount systems, it's crucial to weigh the initial costs of materials and installation. Aluminum ground mounts typically involve higher upfront materials costs but offer savings in labor due to their lighter weight and easier handling. Steel structures, while generally more affordable in raw pricing, tend to incur higher transportation and installation expenses because of their heavier nature. Industry reports suggest that the total cost for aluminum systems can be competitive over time, particularly when factoring in reduced installation labor. This financial assessment crucially assists in making informed decisions about the best material for specific project needs.

Recyclability and End-of-Life Value

Aluminum systems often present a more sustainable option due to their high recyclability and end-of-life value. Aluminum's ability to be recycled multiple times without losing quality results in a reduced environmental footprint compared to steel. Additionally, aluminum recycling rates are high, enhancing its resale value, which contributes significantly to the lifetime value of the systems. For those interested in sustainability, aluminum offers tangible benefits over steel by promoting resource conservation and potential long-term financial returns from recycling efforts.

ROI Considerations for Commercial vs. Residential Projects

Return on investment (ROI) varies significantly between commercial and residential ground mount projects. Commercial investors often benefit from energy savings across larger scales, with the potential for expedited payback periods on their investment. In contrast, residential projects focus on smaller-scale energy savings, which may extend the ROI timeline. Data on energy production—such as annual kilowatt-hour savings—and cost reductions over time help quantify these differences, offering valuable insights for potential investors. For both sectors, evaluating ROI upfront ensures that investments align with financial goals and energy efficiency objectives.

FAQ

What are the main differences between aluminum and steel ground mount systems?

The main differences between aluminum and steel ground mount systems lie in their composition, weight-to-strength ratios, and design flexibility. Aluminum is lightweight and highly resistant to corrosion, making it ideal for humid or salt-exposed environments. Steel, however, is stronger and better suited for load-bearing applications, although it requires treatments like galvanization to prevent rust.

How do aluminum and steel systems compare in terms of maintenance?

Anodized aluminum typically requires less maintenance over time due to its corrosion resistance. Galvanized steel, while durable, may incur higher maintenance costs due to treatment needs in harsh conditions.

Are aluminum systems more sustainable than steel?

Yes, aluminum systems are considered more sustainable because they are highly recyclable and have a lower environmental footprint compared to steel. Aluminum's recyclability contributes to end-of-life value and potential financial returns.

What should be considered when choosing between earth anchor systems and concrete foundations for solar installations?

Choosing between earth anchor systems and concrete foundations depends on site-specific conditions. Earth anchors are more labor-efficient and cost-effective, while concrete foundations may be necessary for more challenging terrains. Soil type and geotechnical analysis should guide the decision.

Table of Contents

- Aluminum vs. Steel Ground Mount Systems: Core Material Differences

- Durability Showdown: Corrosion Resistance and Environmental Performance

- Structural Capabilities for Solar Installations

- Installation Realities: Labor, Foundations, and Site Considerations

- Cost-Benefit Analysis: Initial Investment vs. Lifetime Value

-

FAQ

- What are the main differences between aluminum and steel ground mount systems?

- How do aluminum and steel systems compare in terms of maintenance?

- Are aluminum systems more sustainable than steel?

- What should be considered when choosing between earth anchor systems and concrete foundations for solar installations?